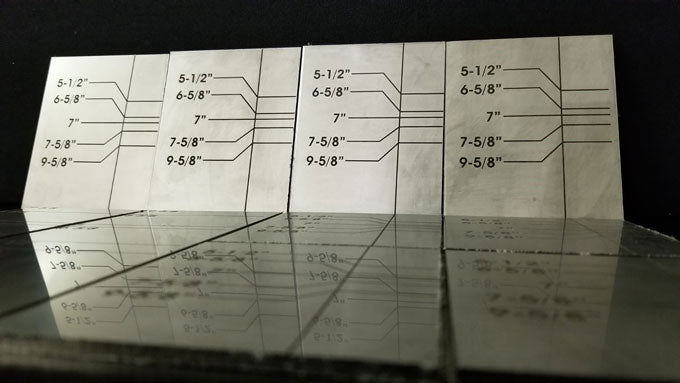

Engraving Services

Industrial Laser Engraving

Laser engrave your barcodes, serial numbers, text, and logos. Our fiber laser machines can engrave or mark all types of metals including stainless steel, aluminum, tool steel, brass, titanium, and much more, allowing you to create a variety of mark types in no time! Whether you're engraving one product label at a time or a table full of components. Give us a call today and asked to speak to one of our sales associates to help you.

Fibermark Engraving Material Compatibility

Fibermark Laser Compatible Materials

| Mark | |

|---|---|

| 17-4 PH Stainless Steel | x |

| 303 Stainless | x |

| 4043 Steel | x |

| 6061 Aluminum | x |

| Bayer 2807 Makrolon polycarbonate | x |

| Bayers Bayblend FR 110 | x |

| Black/White ABS | x |

| Brass | x |

| Brushed Aluminum | x |

| Carbon Fiber | x |

| Carbon Nanotube | x |

| Clear Coat Anodized Aluminum | x |

| Cobalt Chrome Steel | x |

| Colored Delrin (Black/White) | x |

| Compacted Powder Iron w/Iron Phosphate Coating | x |

| Copper | x |

| DAP - Diallyl Phthalate | x |

| GE Plastics Polycarbonate Resin 121-R | x |

| Glass Filled PEEK | x |

| Glass Filled Telfon | x |

| Hard Coat Anodized Aluminum | x |

| Machine Tool Steel | x |

| Magnesium | x |

| Metal Plated Ceramics | x |

| Molybdenum | x |

| Nickel Plated 1215 Mild Steel | x |

| Nylon | x |

| Polybutylene Terephthalate | x |

| Polysulphone | x |

| Rynite PET | x |

| Santoprene | x |

| Silicon Carbide | x |

| Silicon Steel | x |

| Silicon Wafers | x |

| Various Inconel Metals (Nickel-Chromium Super Alloys) | x |

| White PEEK | x |

| Yellow Chromate Aluminum | x |

| Zinc Plated Mild Steel | x |

Co2 Laser Engraving

Laser engraving requires the use of a laser to mark or etch the surface of an award. It can also be used on glass, leather, marble, metal, plastic, stone, and other natural materials and has numerous advantages. Laser engraving can be completed quickly and leaves behind a clean, crisp, and permanent mark that is easy to see. To the touch it is almost impossible to feel the depth of the etching. It is ideal for photos, graphics, and logos because it is highly accurate and has the ability to engrave more than 1000 dots per inch. Not only are we able to engrave, but we are able to cut on materials.

Co2 Laser Engraving Material Compatibility

CO2 Laser Compatible Materials

| Engrave | Cut | |

|---|---|---|

| Wood | x | x |

| Acrylic | x | x |

| Fabric | x | x |

| Glass | x | |

| Coated Metals | x | |

| Ceramic | x | |

| Delrin | x | x |

| Cloth | x | x |

| Leather | x | x |

| Marble | x | |

| Matte Board | x | x |

| Melamine | x | x |

| Paper | x | x |

| Mylar | x | x |

| Pressboard | x | x |

| Rubber | x | x |

| Wood Veneer | x | x |

| Fiberglass | x | x |

| Painted Metals | x | |

| Tile | x | |

| Plastic | x | x |

| Cork | x | x |

| Corian | x | x |

| Anodized Aluminum | x | |

| Stainless Steel | * | |

| Brass | * | |

| Titanium | * | |

| Bare Metals | * |

Diamond Drag Engraving Material Compatibility

Diamond Drag Engraving Compatible Materials

| Mark | |

|---|---|

| 17-4 PH Stainless Steel | x |

| 303 Stainless | x |

| 4043 Steel | x |

| 6061 Aluminum | x |

| Brass | x |

| Brushed Aluminum | x |

| Clear Coat Anodized Aluminum | x |

| Cobalt Chrome Steel | x |

| Compacted Powder Iron w/Iron Phosphate Coating | x |

| Copper | x |

| Glass | x |

| Gold | x |

| Hard Coat Anodized Aluminum | x |

| Machine Tool Steel | x |

| Metal Plated Ceramics | x |

| Nickel Plated 1215 Mild Steel | x |

| Pewter | x |

| Silicon Steel | x |

| Silver | x |

| Various Inconel Metals (Nickel-Chromium Super Alloys) | x |

| Yellow Chromate Aluminum | x |

| Zinc Plated Mild Steel | x |

Sand Engraving

Sand etching (also referred to as sandblasting, or sand carving) as compared to other machine-made engravings is done by hand and therefore a labor-intensive process. It can produce a deep, permanent mark, frosted surface, or somewhere in between. It also allows for greater flexibility in design.What all goes into sandblasting?

Once our customers have their product to be engraved and the components of their design, it is off to artwork. There are countless designs that can be sandblasted onto glass, or crystal among other materials. Basically, just about anything that can be created within the computer software can be etched. Although vector art, which is made up of lines and shapes can be easily altered, some of the challenges to the artwork step include fonts with extremely fine lines, curves or ridges on an item, and too much text or graphics in general. Once the artwork is approved, a film or stencil is created of the artwork and applied to the product.

The product is then properly prepped to be carved. The product is blasted with a stream of pressurized abrasive (typically sand) in a special cabinet. Sand blasts away at the open areas of the stencil on the surface of the product and erodes the surface leaving behind the engraved design with a frosted appearance. The advantage to this method is that the engraving has depth, as this is done by hand you can engrave deeper but must be aware that it may cut directly through glass products.

Overall, sandblasting has a higher perceived value due to its elegant and much more expensive look.

Sand Engraving Material Compatibility

Engraving Compatible Materials

| Mark | |

|---|---|

| Whiskey Glass Sets | x |

| Wine Glass | x |

| Glass Bottles | x |

| Crystal Awards | x |

| Beer Glass Mugs | x |

| Beer Pitchers | x |

| Glass Decanters | x |

| Glass Plates | x |

| Glass Awards | x |

| Custom Glass Signs | x |

| Martini Glass Cups | x |

| Margarita Glass Cups | x |

| Glass Jars | x |

| Glass Candles | x |

| Shot Glass Sets | x |

| Champagne Flute | x |

| Cologne Glass | x |

| Glass Flask | x |